Sheet Metal Laser Cutting

Investing in the latest equipment has helped KSM industries provide the very best sheet metal laser cutting.

We are committed to continuous improvement to help reduce the time it takes from your initial order to finished goods.

Several lasers and a multi-function turret press punch laser cut metals up to 1/2” thick. Automated sheet metal laser cutting machines stand ready to work around the clock to begin the fabrication process.

Multiple Lasers for Maximum Accuracy, Efficiency, and Productivity

Our Mazak lasers are tied into FMS material handling systems for “lights out” operation.

Mazak 8K OPTIPLEX NEXUS FIBER and Automation System

- Automated setup function speeds up overall throughput

- Intelligent monitoring for less operator involvement

- Faster, more accurate cutting

- Ability to cut thicker metals

2 Mazak SUPER TURBO-X MARK II

- 4000W lasers (1”cap.) with FMS material handling

1 Mazak SUPER TURBO-X MARK II

- 1500W laser (3/8”cap.) with FMS material handling

- 60” x 120” max. sheet size all

Laser / Turret Punch Equipment Helps Increase Throughput

The Amada Acies laser and turret punch machine is ideal for a wide mix of production needs at varying quantities. Because this powerhouse machine can do it all: punch, form, roll, mark, emboss, and tap metal, it minimizes wait time and has increased overall throughput.

Based on your drawings and our technician’s programming, the Amada turret punch can accurately extrude holes, louvers, tabs, and knock-outs for seemingly infinite geometries.

We make it a precise and fast part of the overall fabrication process that is truly tailored to your specifications.

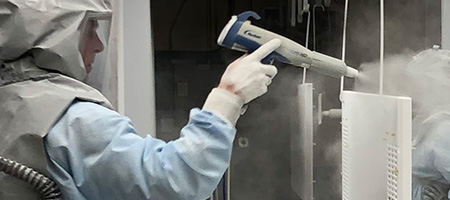

Learn how the Acies and automation helped KSM Industries achieve 60-70% throughput savings in this video:

Amada Acies 2515T

- 33 Ton Combination Turret Punch Press and 4000W Laser with high-capacity tool storage and automatic tool changer

- (1/4” cap.)

- 60″ X 120″ max. sheet work area

- 4 tapping heads, auto load/unload of blanks as well as automated parts picking

- Single setup for custom embossing, perforated panels, tapped holes, tread plates and more

- Minimizes handling

- Supports complete part processing

- Reduces the need for secondary operations

Additional Cutting Options

Beyond our lasers, KSM Industries has additional sawing, drilling, and standard shears available whenever needed.