Sheet Metal Forming

When it is time for sheet metal forming, KSM has eight press brakes for bending and forming metal in a variety of ways

Our team of skilled technicians can handle a variety of complex bends and fabrications with our state-of-the-art equipment.

KSM Press Brakes

- Range from 49 to 350 tons of pressure

- Support European and American style tooling

- Provide consistent performance

- Mechanical, hydraulic, electric

- Updated CNC controls save on manufacturing costs and speed up production

Super-Fast Metal Forming

One of our machines, the Salvagnini P-2 Panel Bender, can complete an average of 17 bends per minute. Ideal for batch or kit production, the universal bending tools automatically adjust in-cycle without the need for re-tooling. This is just one piece of equipment that we use to improve the overall cycle time for your contract fabrications.

More Efficient,

Electric Press Brakes

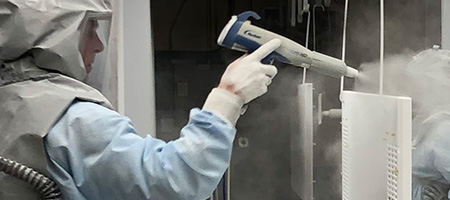

Two Safran E-Brake machines help increase productivity while providing energy savings. Using a fully electric drive, Safran E-brakes are virtually noiseless. In addition, an ergonomic design provides lift assistance to our techs.

Cylindrical Component Forming

Two in-house pyramid rolling mills allow us to easily roll-form metal. Our mills can roll material up to ¼” thick and up to 5’ wide.