Capabilities & Equipment

American Custom Metal Fabricating

KSM Industries has invested in cutting-edge manufacturing equipment and training our employees to provide the highest quality American custom metal fabricating services.

From start to finish, our production team handles your custom order with precision to quickly and accurately deliver what you need. With the help of Quick Response Manufacturing Cells, we arrange the necessary equipment and staffing to reduce lead times.

At every stage of the process, we utilize a one-over-one inspection policy. This is just one of our quality control methods. As an added checkpoint, KSM manufacturing technicians use our InspecVision Planar 2D inspection machine to verify product quality within a matter of seconds.

The Metal Fabricating Process

The following steps are part of our custom metal fabricating process:

- CAD / CAM Engineering Review

- Design for Manufacturability

- Laser Cutting

- Sawing

- Drilling

- Punch Press

- Panel Bending

- Forming

- Roll Forming

- Tapping

- CNC Machining

- Vibratory Deburring

- Various Grades of Metal Finishing

- Hardware Insertion

- Robotic and Manual Welding

- Quality Inspection (throughout every step)

- Power Washing

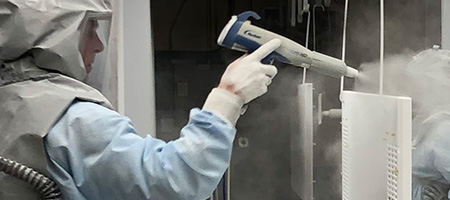

- Powder Coat Painting

- Assembly

- Packaging

- Kitting

- Shipping

Learn More About our In-House Fabricating

We’re proud of our vast expertise in American custom metal fabricating. And we invite you to learn more about the key phases of our fully integrated, in-house fabrication process.

Want to get started right away?

Complete our Sheet Metal Fab Quote Form.