Engineering Services Design for Manufacturability

KSM engineers act as an extension of your engineering team to review design for manufacturability for every project.

Our engineering services work with current drawings or create new drawings for your contract fabrications to identify and eliminate manufacturing issues.

Quality and Cost Improvement

The Design for Manufacturability (DFM) methods are important for two reasons:

- DFM assesses overall feasibility of manufacture

- DFM finds opportunities for cost reduction

Quality and Cost Improvement

KSM engineers help find and address manufacturing concerns before cutting and forming metal.

The first question they approach is: can this part be effectively fabricated with its current design, cost, and distribution specifications?

To start, our engineers thoroughly review your designs on Solid Works or AutoCAD.

Then, they review the manufacturing process to uncover potential opportunities for cost savings. As part of design for manufacturing, KSM engineers may recommend design alterations and compare design alternatives that have different price points based on the manufacturing process. Some design features may unnecessarily require additional manufacturing operations.

KSM engineers helps customers understand how initial design choices could potentially create production concerns. This comprehensive engineering review reduces the need for costly rework, which saves time, effort and money.

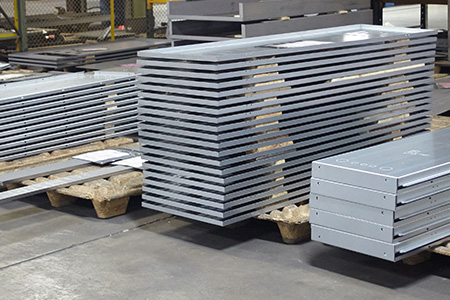

After customer approval, we start the manufacturing process with stringent quality controls in place to ensure your order is on-spec. Learn more about our internal quality programs. With each and every project, our goal is the highest quality end product fabricated efficiently at a competitive price.