Quick Response Manufacturing

Quick turnaround for custom orders

Quick Response Manufacturing has transformed KSM Industries’ manufacturing and operational practices.

Building on our existing Lean and Six Sigma principles, Quick Response Manufacturing, or QRM, has helped KSM focus on overall time-based management to more quickly turnaround production orders.

What is QRM?

Quick Response Manufacturing is a business-wide strategy to reduce lead times throughout manufacturing and office processes that has been around since the early 1990’s.

QRM consists of four core concepts:

- The Power of Time

- Organization Structure

- System Dynamics

- Enterprise-Wide Application

Learn more about an overview of QRM

Quick Response Manufacturing is ideal for high-mix, low-volume manufacturers like KSM Industries as a way to reduce unnecessary lead times.

In 2015, KSM turned to the University of Wisconsin-Madison’s Center for Quick Response Manufacturing for continued professional development. KSM employees received a certificate in QRM and have since returned for additional training.

Reducing Lead Times

Using QRM, we are able to uncover the causes for long lead times, and provide tools to eliminate them throughout our operation. It has allowed us to improve our response time and become a better, more efficient partner to our customers.

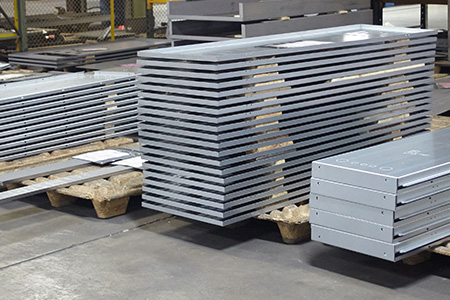

Our QRM journey started with electrical enclosures and panels and has expanded to construction equipment and components for the defense market.

Advantages of Quick Response Manufacturing Cells

- Focused approach on specific types of parts

- Most processes and equipment required to make these products are located entirely in that cell

- Team member cross-training allows systematic use of all equipment as work flow dictates

The end result of QRM: faster throughput in each step of the fabrication process and shorter turnaround times