Metal Fabrication Equipment

KSM utilizes industry leading fabrication equipment, and employs a team of experts to run it!

Shear

- Cincinnati 1/4” x 10’

Lasers

- Mazak 8K Fiber Laser with full automation and an 18-shelf tower

- (2) Mazak SUPER TURBO-X MARK II

- 4000W Co2 lasers (1”cap.) with FMS material handling

- 60” x 120” max. sheet size

Punch Presses

- Amada Acies 2515T

- 33 Ton Combination Turret Punch Press and 4000W Laser with high capacity tool storage and automatic tool changer

- (1/4” cap.)

- 60″ X 120″ max. sheet work area

- 4 tapping heads, auto load/unload of blanks as well as automated parts picking

- Amada 367 Vipros

- 33 Ton Turret press

- (1/4” cap.) with auto index tool holders

- 60” x 72” max. sheet work area

- Amada 345 Pega King

- 33 ton Turret press

- (1/4”cap.) with auto index tool holder

- 39” x 50” max. sheet work area

Forming

- Amada Promecam HFB 220 ton X 14’

- Amada HFE 170-3s 187 ton X 12’

- Amada HFE 80 80 ton X 8’

- Amada HFE 80 M2

- Cincinnati 350 ton X 14’

- Safan 35-1250 electric brake

- Safan 200-4100 electric brake

- Salvagnini P-2 Panel Bender

Welding

- 2 – Genesis Versa 2, Fanuc Robotic weld cells, each with 2-4×10′ picture frame positioners to handle your large volume or complex weldments

- Miller/Performarc Panasonic Robot Weld Cell

- Full capability of MIG, TIG, Flux Core and Pulse arc welding on mild steel, stainless steels, and aluminum

- Drawn-Arc stud welders

- Numerous Capacitor-Discharge stud weld machines

- Rocker arm and press type resistance welders from 75 to 150KVA

- State of the art Lincoln and Miller equipment with advanced process controls

- Staff certified to: MIL-STD-248(D), AWS or ASME Sect. IX

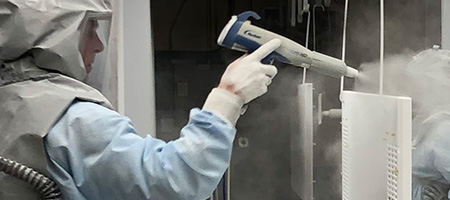

Powder Coat

- Conveyorized five stage iron phosphate power wash with 2019 Nordson HD powder booths with 10 fluidizing hoppers with quick color change capability. Reduced line length to turn product faster.

- Max Cube 52” (1.32M) Wide by 72” (1.83M) High by 160” (4.06M) Long

- Maximum Weight 1100 pounds (500kg)

- Batch steam cleaning, off-line powder booth and bake oven.

- Off-line Powder Paint System

- Max Cube 90” (2.29M) Wide by 105” (2.67M) High by 160” (4.06M) Long

- Lengths over 160” can be accommodated as width is reduced

Miscellaneous Equipment

- Pyramid Mills for Roll Forming

- Haeger Insertion Presses for hardware insertion

- Auto-Sert Hydraulic presses for hardware insertion

- Clausing CNC Bed Mill

- Flex-Arms for thread cutting/tapping/spot-facing

- Marvel 380A-PC60 programmable vertical band saw

- Various manual machines: Strippit manual punch, band saw, drill presses, radial arm drill.

- Zehnder Air filtration systems

- Conventional and Vibratory deburring